Development and Technology Information (New Materials & Advanced Optical Solutions)

Isuzu Glass participates in joint development with Kyoto Institute of Technology, Osaka Univ, Shiga prefecture Univ, Hokkaido Univ and

The National Institute of Advanced Industrial Science and Technology (AIST).

We pursue the refinement of our core technology "Glass melting" and "Molding technology" and look for innovative ways to advance our technology to fulfill new business fields.

Moldable UV-transmitting glass IHU200, IHU200LM

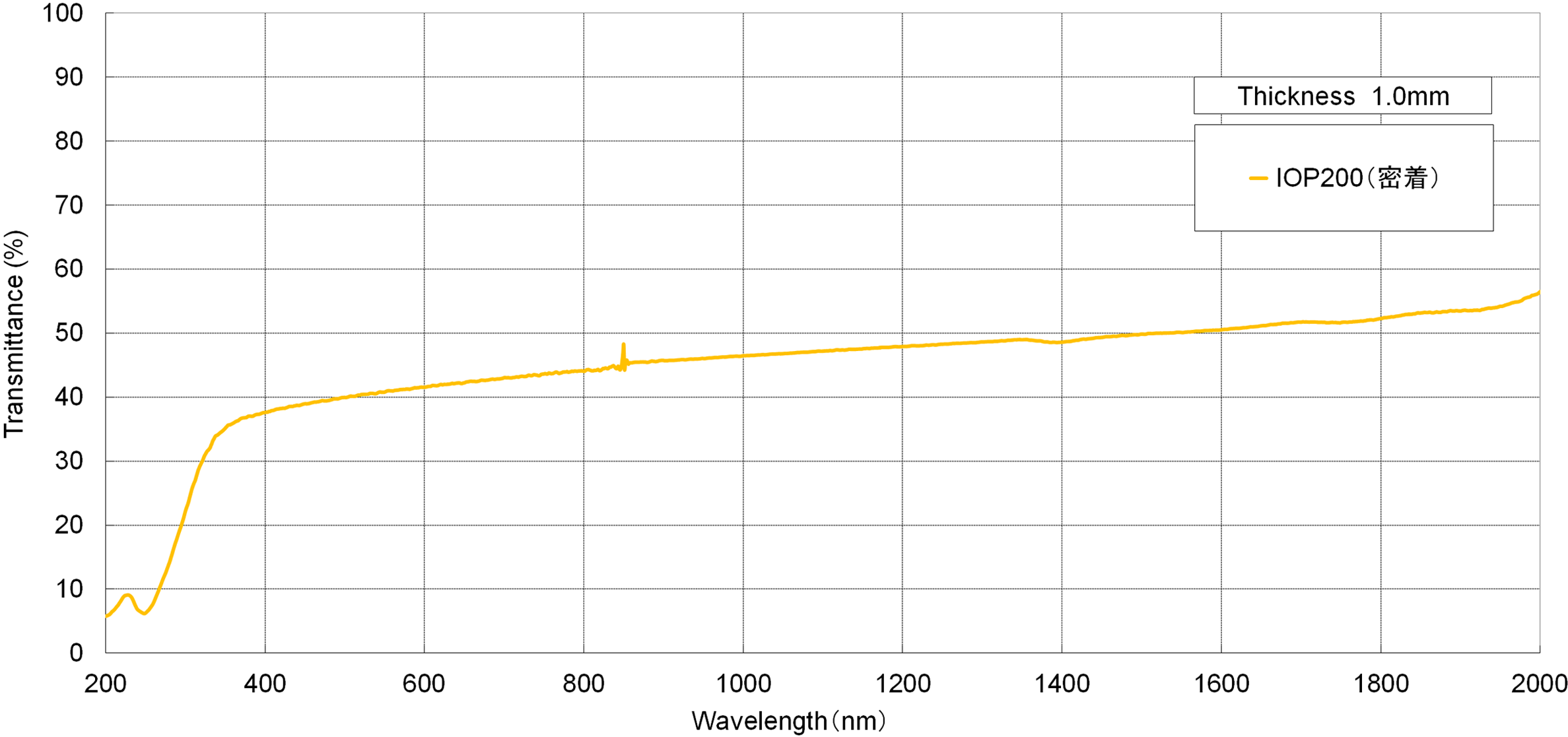

Opal glass diffuser (IOP200)

IOP200, an opal diffusion glass with properties similar to Lambertian light source in the ultraviolet, visible, and near-infrared ranges, had been completed deverloment and available now. Comparing to the current IOP010, which is used in the visible to near-infrared range,the new product IOP200 has a diffusion effect at the ultraviolet range.

Optical wireless power transmission and lens array

Isuzu Glass Lens Array, one our main products, is currently being applied for optical wireless power transmission. Associate Professor Miyamoto Tomoyuki of Laboratory for Future Interdisciplinary Research of Science and Technology (FIRST), Institute of Innovative Research (IIR), Tokyo Institute of Technology, who is leading the Study Group of Optical Wireless Power Transmission, informed us about the latest information of this system in 2024.

Double-sided molded lens

We are developing a double-sided lens array integrally molded, which was previously manufactured by laminating. Since it is not bonded, the adhesive does not burn due to a high power light source such as laser. We can achieve optical axis tolerance of ± 0.05 mm, comparing present laminated lens tolerance of ± 0.1 mm. Both prototyping and mass production is OK for us.

-

※This is a prototype 3D model. If you drag the model with the mouse, it will rotate according to the movement of the mouse. You can also zoom in / out the model by scrolling the mouse wheel.

-

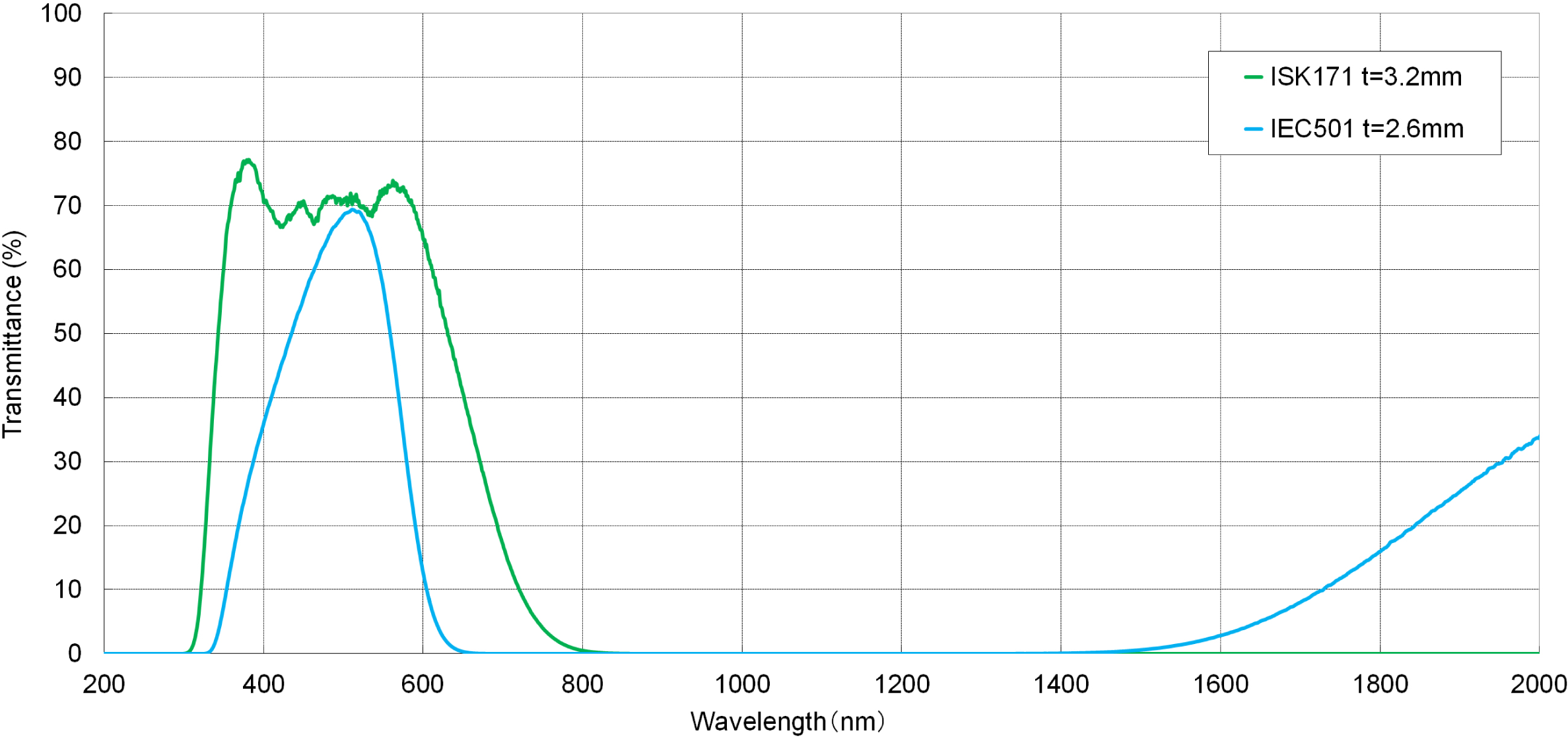

Laser protective goggles

High density IR absorbing filter

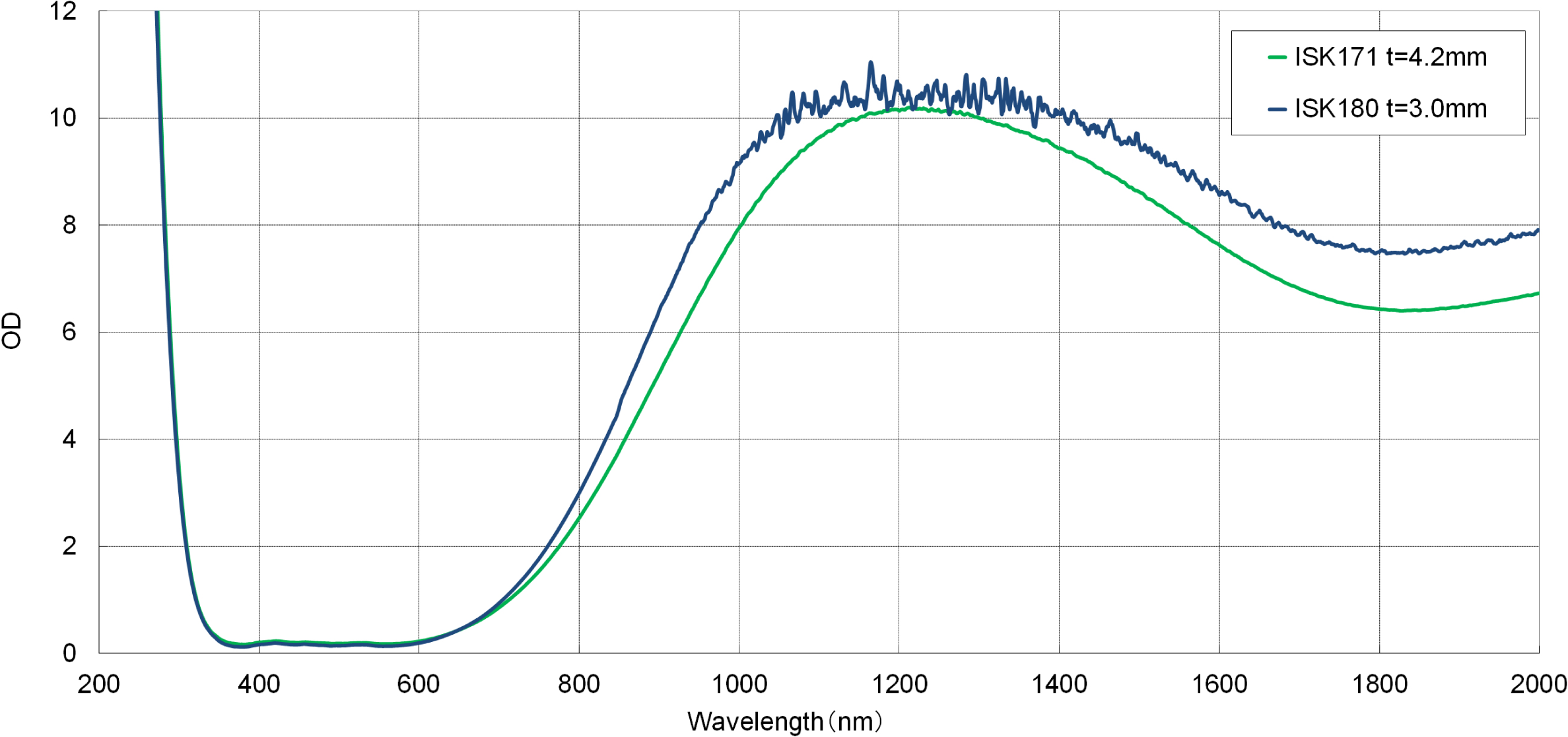

We have successfully developed a glass with an even higher optical density than ISK171, which was previously considered to have the highest OD value (optical density) at the YAG laser wavelength (1064nm).

This high-density product ISK180 has an optical density 1.5 times higher than the conventional product ISK171 mentioned above. Production is currently underway with the goal of completing development in December 2025.