Integrated Lens Arrays / Microlens Arrays (Fly’s Eye Lenses)

Our lens array is made by mold pressing.

Traditionally, lens arrays were made by bonding cell parts one by one, but it is now possible to make them together as a plate using a mold.

Pressed by mold can provide cost merit over laminated products, while makes mass production possible.

Lens cells can be not only spherical surfaces, but also of variety of shapes such as aspherical, cylindrical, irregular, eccentric, etc.

Micro lens arrays with tiny cells and double-side lens with two different shape of surface can also be produced.

We also have standard products which do not need mold offered by customer. Pleaes consult us for details.

Application

Semiconductor equipment, visual inspection equipment, FA equipment, projectors, 3D printers, etc.

Keyword

Uniform light, lens array, fly eye, integrator lens, microlens array, double-sided lens array, honeycomb

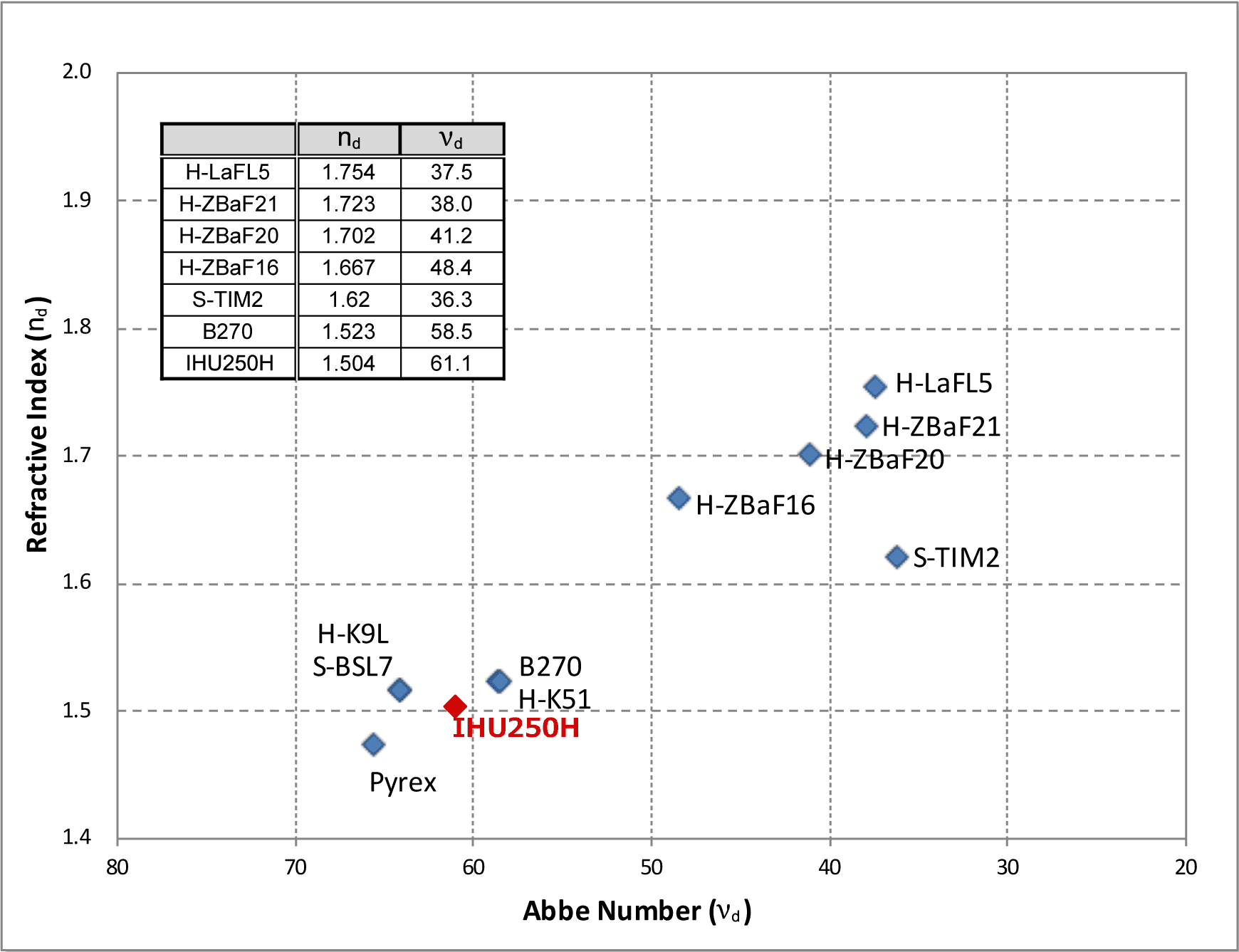

Moldable material

We can mold various kinds of glass materials. Materials are not listed in the table might also be possible to be molded. Please feel free to contact us.

Spec sheet

| Item | Lens array | Micro lens arrays | Double-sided lens array |

|---|---|---|---|

| Diameter (Max) | 130✕130mm | 130✕130mm | 60✕60mm |

| Diamter (Min) | 10✕10mm | 10✕10mm | 20✕20mm |

| Cell size (Max) | MAX size within dimension | ||

| Cell size (Min) | 0.2mm | 0.2mm | 0.5mm |

| Center thickness (Max) | 10mm | 10mm | 15mm |

| Center thickness (Min) | 1mm | 1mm | 2.5mm |

| Flange thickness (Max) | 10mm | 10mm | 15mm |

| Flange thickness (Min) | 1mm | 1mm | 2.5mm |

| Radius (Max) | R100mm | R10mm | R100mm |

| Radius (Min) | R0.3mm | R0.3mm | R0.3mm |

| Optical axis tolerance | Optical axis between pitch0.05mm | Optical axis between pitch0.05mm | Optical axis between pitch0.05mm |

*Values here are just examples. Please take as a reference as it will vary depending on specifications and conditions.

If you have a specific shape image or drawing, please send for our checking. Additionally, we can also do optical designs.